The Material Classification Code (MCC) feature in Oracle EBS Item Master Setup is essential for organizing and managing inventory effectively. This feature was added in 12.2.6 and later enhanced in 12.2.10. Businesses leverage this feature for several key use cases:

1. Inventory Organization & Segmentation

Helps categorize items based on their nature, such as raw materials, finished goods, consumables, or hazardous materials.

Facilitates better searchability, reporting, and grouping of items in inventory.

2. Compliance & Regulatory Tracking

Essential for industries like pharmaceuticals, chemicals, and aerospace, where strict regulations govern material handling.

Allows companies to classify materials based on safety regulations, hazardous handling requirements, or environmental constraints.

3. Pricing & Cost Control

Enables businesses to assign unique classification codes that can be used to apply specific pricing models, taxes, or cost tracking.

Helps in budget planning and cost analysis, ensuring proper cost allocation based on material type.

4. Supplier & Procurement Optimization

Helps in supplier-specific classifications, allowing procurement teams to streamline ordering processes.

Assists in bulk purchasing decisions, determining reorder points for different material categories.

5. Forecasting & Demand Planning

Supports predictive analytics, helping businesses anticipate material consumption trends.

Enables optimized stocking levels, reducing the risk of shortages or overstock situations.

6. Production & Manufacturing Efficiency

Improves BOM (Bill of Materials) management, ensuring accurate material selection during manufacturing.

Helps in work order planning, ensuring the right materials are available at the right time for production.

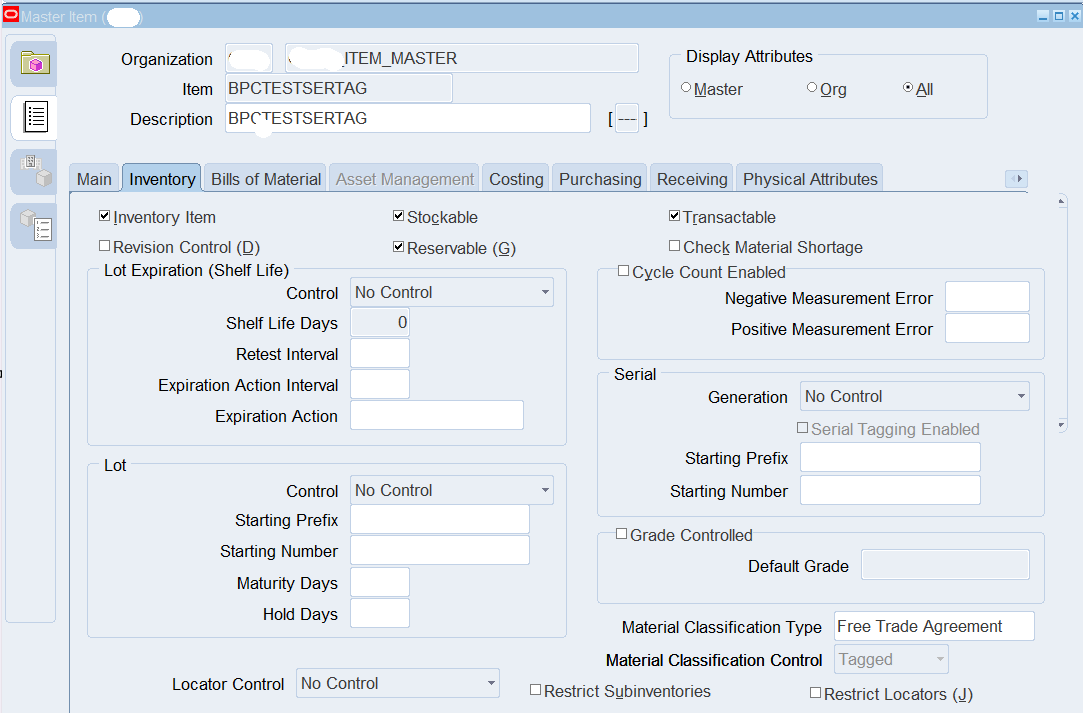

Setup

1. Setup the Classification Type

Inventory Setup --> Lookup

2. Setup Classification Code

Inventory Setup --> Transactions --> Material Classification Code